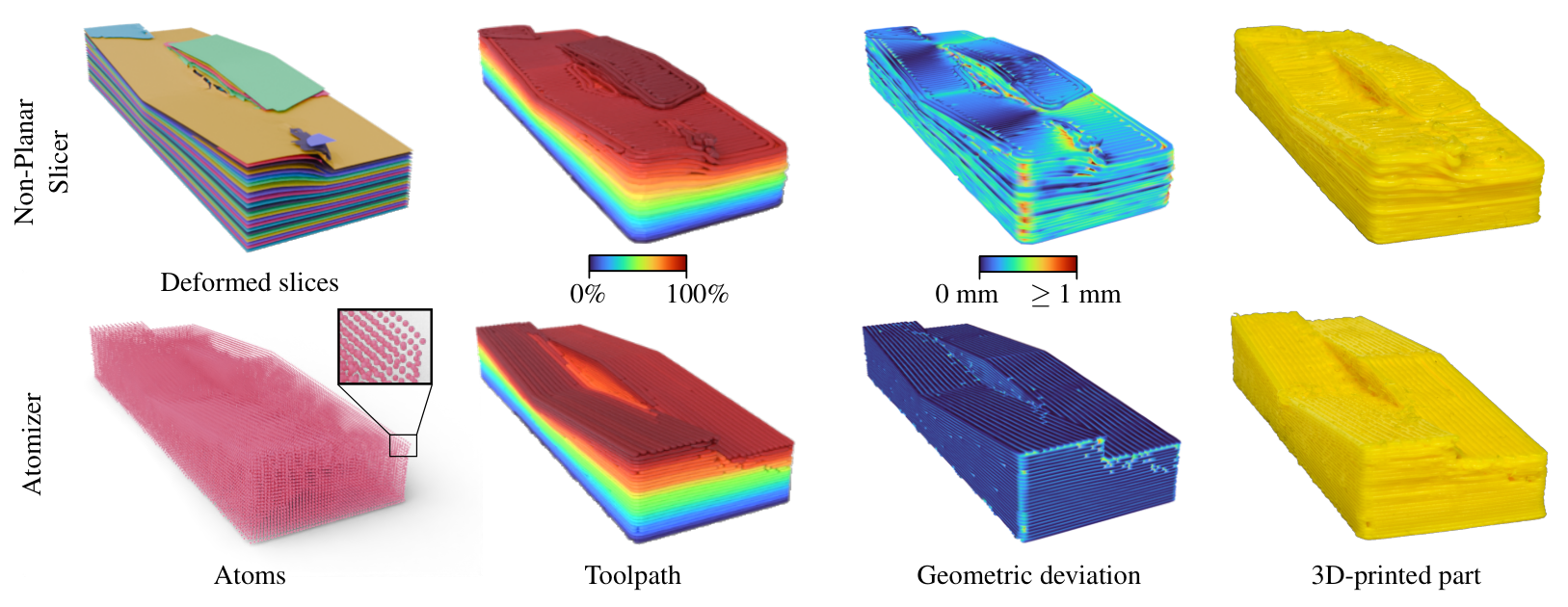

Atomizer - Beyond Non-Planar Slicing for Fused Filament Fabrication

Abstract

Fused filament fabrication (FFF) enables users to quickly design and fabricate parts with unprecedented geometric complexity, fine-tuning both the structural and aesthetic properties of each object. Nevertheless, the full potential of this technology has yet to be realized, as current slicing methods fail to fully exploit the deposition freedom offered by modern 3D printers. In this work, we introduce a novel approach to toolpath generation that moves beyond the traditional layer-based concept. We use frames, referred to as atoms, as solid elements instead of slices. We optimize the distribution of atoms within the part volume to ensure even spacing and smooth orientation while accurately capturing the part’s geometry. Although these atoms collectively represent the complete object, they do not inherently define a fabrication plan. To address this, we compute an extrusion toolpath as an ordered sequence of atoms that, when followed, provides a collision-free fabrication strategy. This general approach is robust, requires minimal user intervention compared to existing techniques, and integrates many of the best features into a unified framework: precise deposition conforming to non-planar surfaces, effective filling of narrow features – down to a single path – and the capability to locally print vertical structures before transitioning elsewhere. Additionally, it enables entirely new capabilities, such as anisotropic appearance fabrication on curved surfaces.

Resources

Article Presentation Supp. video Code Replicability stamp BibTex DOI